Creative Sparks: From Florist to Welder

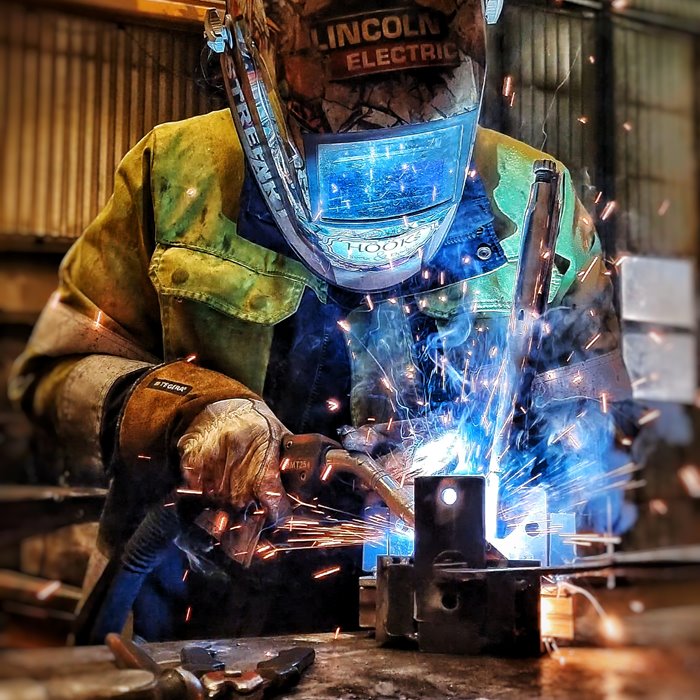

In welding, inspirational stories like Maria Höök's illustrate bravery and dedication. Transitioning from florist to mechanic workshop, Maria's journey exemplifies the transformative power of passion. As a Swedish welder in the mechanic and hydraulic industry, her career underscores the vital importance of workplace safety.

A Leap of Faith and a Flourishing Career

Maria Höök's journey as a welder began with a desire for change. After spending years working in a florist shop, she decided to explore a completely new path that would allow her to express her creativity and work with her hands. In her own words, Maria reflects on her decision, "I got bored from working in a florist shop and decided to try something new. I wanted to work with my hands and do something creative, so I looked around for education to learn a new craft."

This search led her to a welding school, where Maria found a medium that allowed her to combine her love for gardening and her newfound interest in welding. This union of passions sparked a fire within her, ultimately paving the way to a flourishing career.

The Diverse and Fulfilling Role of a Welder

As a welder in a mechanic and hydraulic workshop, Maria Höök's work is diverse and multifaceted. Her workplace specializes in repairing machines and vehicles, along with executing custom projects that involve constructing unique materials and products for clients. From crafting parts for house constructions to creating steel beams, pillars, and custom vehicle components, Maria's skills are put to the test daily.

"My work is very diverse, which allows me to practice most of the common welding techniques on a daily basis," Maria explains. This diversity keeps her engaged and constantly improving her skills, as each project brings new challenges and opportunities for growth.

Maria Höök

Welder and entrepreneur. Follow Marias inspiring and exciting journey on her Instagram - kvinnligsvetsare

Maria's Instagram