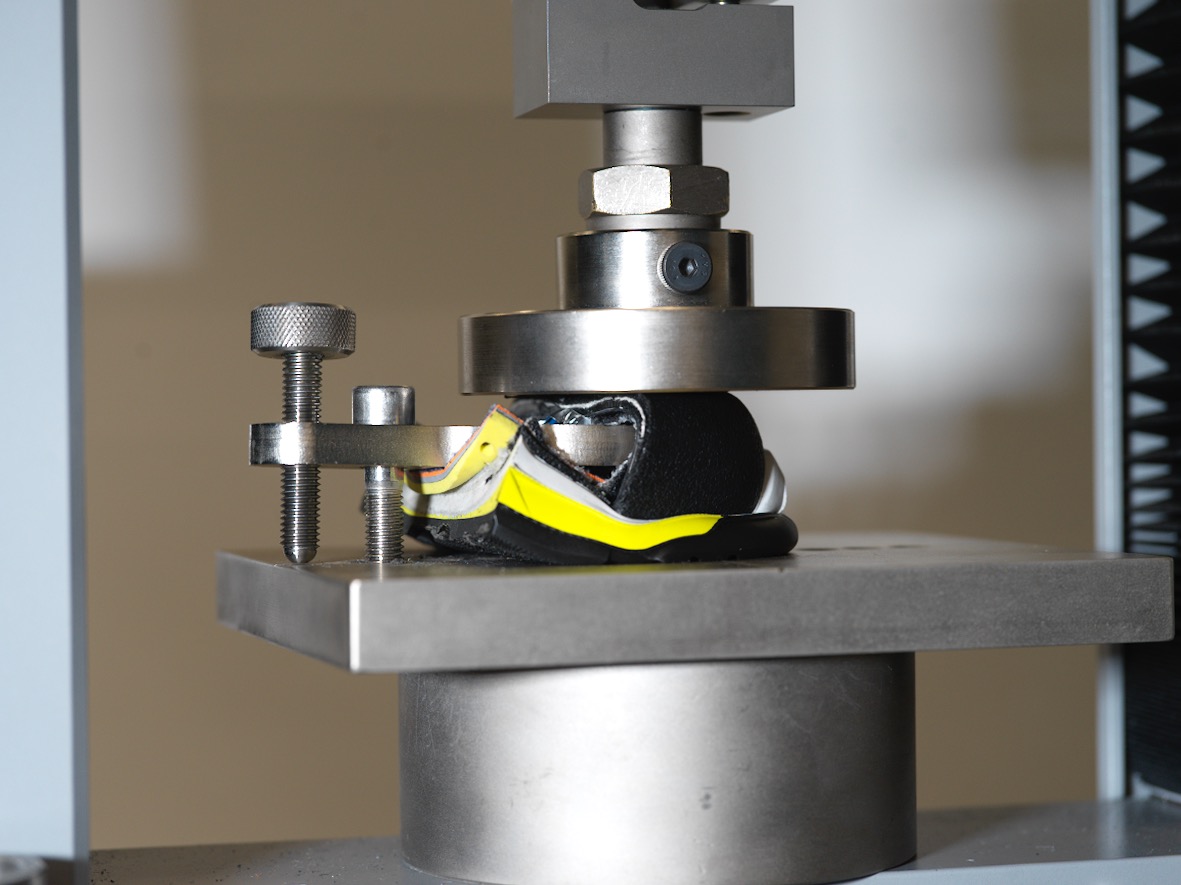

JALAS test lab, an extremely tough environment for work shoes

In the Jokipii village of Jalasjärvi, Finland, a modern laboratory — filled with mechanical and environmental test equipment — torture tests new materials for safety shoes. The shoe materials are repeatedly hit, pricked, pulled and even bent in minus 20°C. Our researchers are searching for the materials’ limits as they apply to their use in JALAS safety shoes.

“We have ten machines and can perform 14 different tests in our Jokipii lab,” says Juho Järvinen, Product Line Director, Footwear at Ejendals. “Then we supplement the machine results with user tests. You can test anti-slip in a lab, but it's only when you're out on slippery ice that you really experience how the material works.”

A lab with many purposes

Because Ejendals makes its own JALAS safety shoes in-house, the Jokipii lab does numerous, ongoing tests to ensure production quality. But the lab also has an important role in product development, guided by Ejendals’ goals for safety, ergonomics, and sustainability.

Juho Järvinen

Product Line Director, Footwear at Ejendals